Sizing a transformer for an industrial plant is not just about adding up motor ratings and picking the next higher kVA. In chemical plants, a wrongly sized transformer can lead to overheating, nuisance tripping, poor power quality, and expensive future upgrades.

In this tutorial, I’ll explain how transformer sizing is actually done in real industrial projects, using a chemical plant example, and I’ll also clarify how DG and UPS sizing philosophies differ.

This is written from a practical plant engineer’s perspective, not a classroom one.

Why Transformer Sizing Matters in Industrial Plants

A transformer is the electrical backbone of a plant. Once installed, changing it is:

- Costly

- Time-consuming

- Operationally risky

Unlike motors or panels, transformers are expected to:

- Run continuously (24×7)

- Handle overloads and starting currents

- Support future expansion

- Tolerate harmonics from VFDs and rectifiers

That’s why design kVA is always higher than actual demand.

Step 1: Understand the Key Electrical Terms

Before calculations, let’s align on terminology that is often misunderstood.

Connected Load

Connected load is the sum of rated power of all installed equipment:

- Motors

- Heaters

- Lighting

- Utilities

- Small power outlets

Important: Connected load is never equal to actual running load.

Maximum Demand (MD)

Maximum demand is the highest load the plant actually draws at any point in time.

It is obtained from:

- Energy meters

- Historical utility bills

- Load studies

This is the real electrical requirement of the plant.

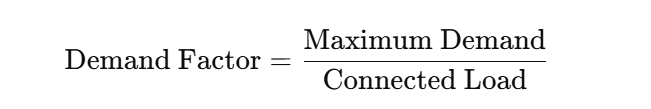

Demand Factor

Typical demand factor in chemical plants:

- 0.6 to 0.75

This means not all equipment runs together.

Diversity Factor

Different sections peak at different times:

- Utilities

- Process

- Packaging

- Admin loads

Diversity helps reduce the total peak load.

Step 2: Prepare the Plant Load List (Example)

Let’s take a realistic chemical plant example.

Connected Load Summary

| Load Type | Power (kW) |

| Process motors (reactors, agitators, pumps) | 600 |

| Utilities (boiler, cooling tower, air compressors) | 300 |

| Lighting & small power | 100 |

| Electrical heaters | 200 |

| Total Connected Load | 1200 kW |

At this stage, many beginners assume:

“I need a 1200 kW transformer.”

That assumption is wrong.

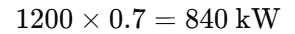

Step 3: Calculate Maximum Demand

Assume:

- Demand factor = 0.7

- Power factor = 0.9

Maximum Demand

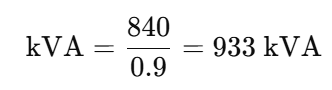

Convert kW to kVA

So, the plant normally operates around 930–950 kVA, not 1200 kVA.

Step 4: Why You Cannot Select a 1000 kVA Transformer

Here’s where design engineering starts.

A transformer must handle more than steady-state demand.

Real-World Design Considerations

- Future Load Growth

- New reactors

- Additional pumps

- Process debottlenecking

- New reactors

- Motor Starting Current

- 5–7× rated current

- Causes voltage dip and heating

- 5–7× rated current

- Harmonics

- VFDs

- Rectifiers

- SMPS loads

- VFDs

- Continuous Duty

- 24×7 operation

- Ambient temperature

- Reduced cooling margin

- 24×7 operation

Practical Design Margin

| Factor | Typical Margin |

| Future expansion | 15% |

| Motor starting | 10% |

| Harmonics & losses | 10% |

| Continuous operation | 10% |

Total margin ≈ 25%

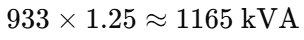

Final Transformer Sizing

Selected Transformer

1250 kVA Transformer

This is why:

- Demand = ~933 kVA

- Design = 1250 kVA

This difference is intentional and necessary.

Step 5: DG Sizing – Completely Different Philosophy

A very common mistake is:

“DG size should be same as transformer.”

That is not always true.

What DG Is Actually Meant For

DG supports:

- Essential process loads

- Safety systems

- Utilities needed to avoid plant damage

DG does not run the full plant.

Identify Critical Loads

| Load | Power (kW) |

| Critical process pumps | 250 |

| Instrument air compressor | 120 |

| DCS & PLC systems | 30 |

| Emergency lighting | 20 |

| Fire water pump | 150 |

| Total Running Load | 570 kW |

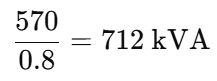

DG Calculation

Assumptions:

- DG power factor = 0.8

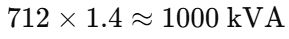

Add:

- Motor starting margin = 30%

- Future margin = 10%

Selected DG

1000 kVA DG Set

This DG can:

- Start motors safely

- Run continuously during power failure

- Avoid wet stacking due to oversizing

Step 6: UPS Sizing – Zero Interruption Philosophy

UPS is not for motors.

UPS is meant for:

- DCS

- PLC

- Analyzers

- Servers

- Interlocks

- Safety systems

UPS Load Example

| Load | Power (kW) |

| DCS & PLC panels | 15 |

| Process analyzers | 10 |

| Servers & networking | 8 |

| Safety systems | 7 |

| Total Load | 40 kW |

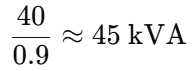

UPS Calculation

Assume:

- UPS PF = 0.9

Add redundancy (N+1):

2 × 60 kVA UPS

Battery backup:

- Typically 30–60 minutes

- Based on plant shutdown philosophy

Transformer vs DG vs UPS – One-Glance Comparison

| Equipment | Based On | Design Philosophy |

| Transformer | Maximum demand + growth | Long-term backbone |

| DG | Essential loads + starting | Emergency survival |

| UPS | Control & safety loads | Zero interruption |

Common Mistakes Seen in Industrial Plants

❌ Selecting transformer equal to connected load

❌ Oversizing DG leading to low loading and wet stacking

❌ Feeding motors from UPS

❌ Ignoring harmonics from VFDs

❌ Not planning for future expansion

Final Thoughts from a Plant Engineer

Transformer sizing is a balance between engineering safety and economic sense.

Too small → overheating and failures.

Too large → unnecessary capital cost and inefficiency.

If you size your transformer based on:

- Real demand

- Practical margins

- Future needs

…it will serve your plant reliably for 20–30 years.